Pace Industries Story

Posted on August 06, 2019

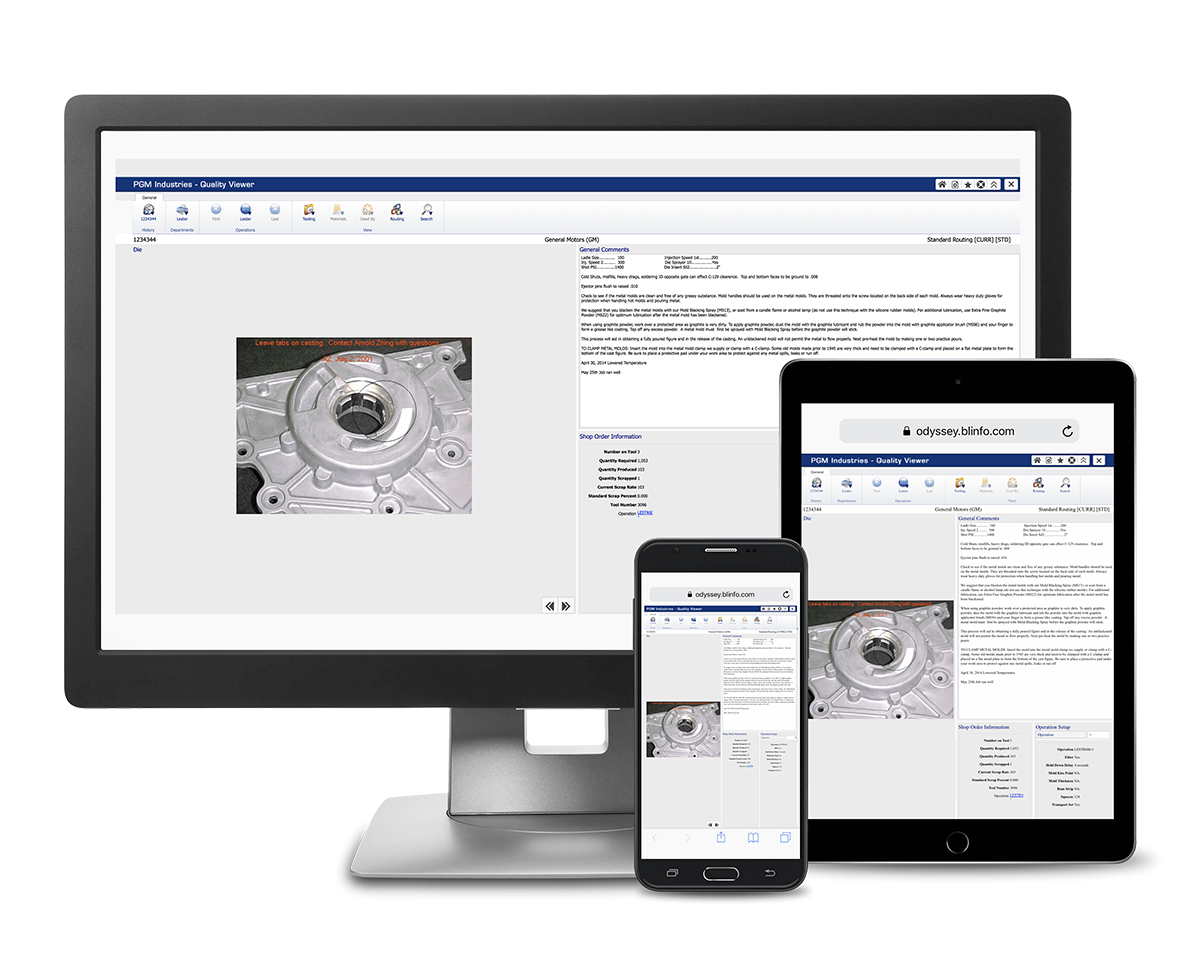

Multi-plant Pace Industries relies on Odyssey to run a more agile, transparent and efficient operations at all 15 plants with ERPAt the heart of quality die castings is the tooling and die cast machine, and all the quality and business processes supporting them. Odyssey helps die casters monitor tooling cycles down to the cavity level and provides notifications when thresholds are exceeded. Scheduling and tracking actual die cast machine maintenance. Managing post casting operations of parts, including internal and out sourced machining, painting, anodizing, etc. is an integrated part of the Odyssey ERP system for die casters.

As a die caster, you have special requirements. B&L Information Systems serves only metalcasters, and we developed Odyssey ERP software to directly address the specific needs of die casters. From companies with ten employees to thousands, many of the industry's leading die casters rely on Odyssey, the die casting ERP system. Odyssey fits your business because we developed it through direct involvement from people like you, people with first-hand knowledge. And it unites all areas of your business: manufacturing, quality, sales, finance, inventory and data analytics.

Posted on August 06, 2019

Multi-plant Pace Industries relies on Odyssey to run a more agile, transparent and efficient operations at all 15 plants with ERPPosted on January 03, 2022

RCM Industries has used B&L Information Systems Odyssey ERP Software for 16 years for one simple reason: “It was the best ERP system specifically tailored to the foundry/die casting industry.”Posted on August 23, 2018

Dyersville Die Cast boosts productivity with Cloud-based Odyssey ERP

Posted on July 20, 2017

LEAN die caster Acme Alliance, LLC relies on the Software as a Service (SaaS) Odyssey ERP system from Progress Partner, B&L Information Systems, to optimize operations while reducing costs.For more information on the leading ERP for metalcasters, please get in touch with us using the form below.