Eagle Precision Cast Parts Story

Posted on April 24, 2018

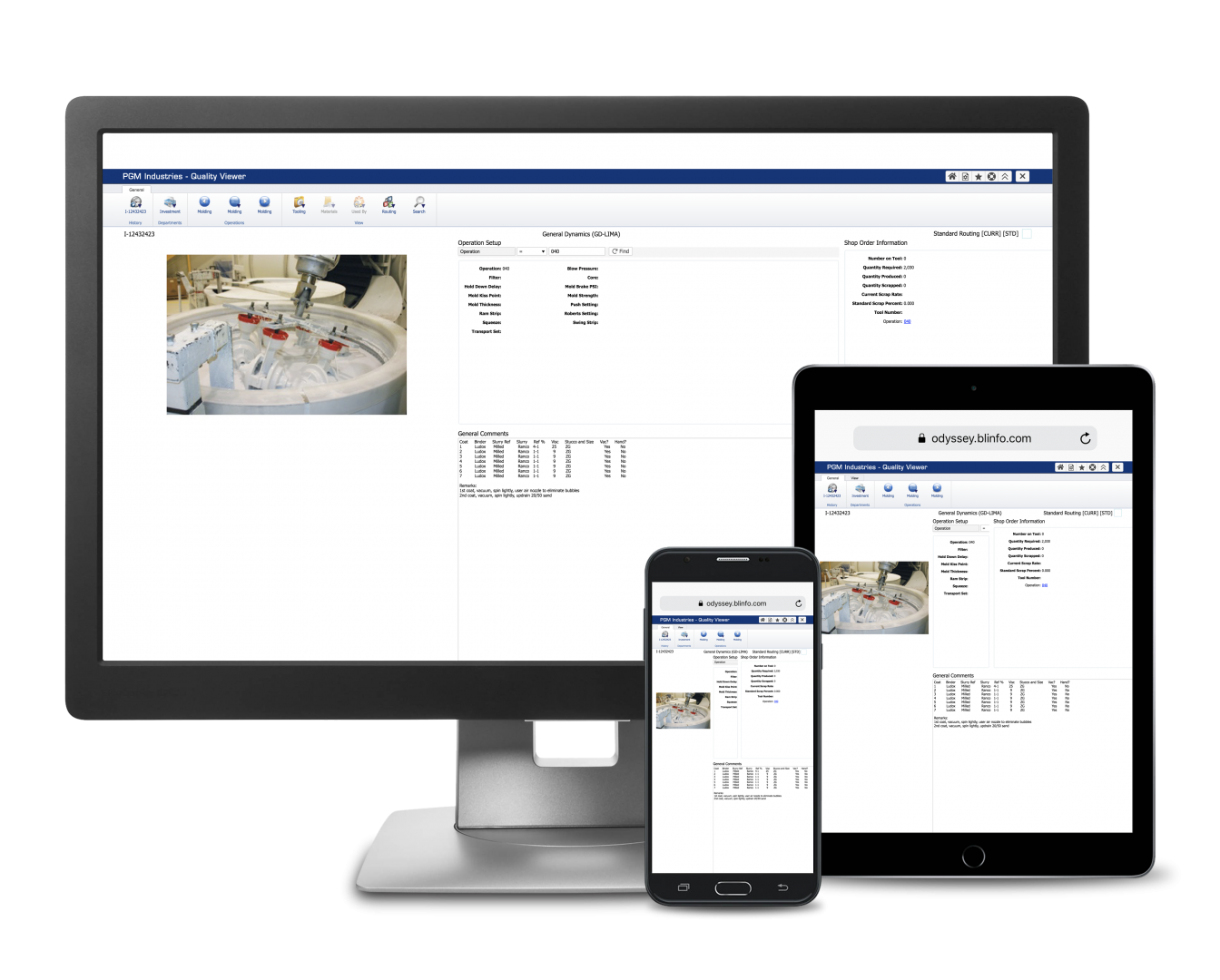

Eagle Precision Cast Parts optimizes lead time, on-time delivery, quality and more with the fully integrated Odyssey ERP system.The investment casting process has an intricate nature. Odyssey helps track inventory of wax assembles after injection, assembled trees during drying, or castings after pouring and knock off. Managing post casting operations of parts, including internal and outsourced machining, painting, anodizing, etc. is all integrated into the Odyssey ERP system for investment casters.

As a investment caster, you have special requirements. B&L Information Systems serves only metalcasters, and we developed Odyssey ERP software to directly address the specific needs of foundries, die casters, investment casters and related operations. From a dozen employees to thousands, many of North America's leading investment casters rely on Odyssey, the investment casting ERP system. From pre-casting sales activities to post-casting operations, Odyssey can help you manage your unique manufacturing process with efficiency and real-time clarity. Odyssey fits your investment casting business because we developed it through direct involvement from people like you, people with first-hand knowledge. And it unites all areas of your business: manufacturing, quality, sales, finance, inventory and data analytics.

As a investment caster, you have special requirements. B&L Information Systems serves only metalcasters, and we developed Odyssey ERP software to directly address the specific needs of foundries, die casters, investment casters and related operations. From a dozen employees to thousands, many of North America's leading investment casters rely on Odyssey, the investment casting ERP system. From pre-casting sales activities to post-casting operations, Odyssey can help you manage your unique manufacturing process with efficiency and real-time clarity. Odyssey fits your investment casting business because we developed it through direct involvement from people like you, people with first-hand knowledge. And it unites all areas of your business: manufacturing, quality, sales, finance, inventory and data analytics.

Posted on April 24, 2018

Eagle Precision Cast Parts optimizes lead time, on-time delivery, quality and more with the fully integrated Odyssey ERP system.How does Odyssey work in a company? A real customer, Eagle Precision Cast Parts, shares an overview of how they use Odyssey.

For more information on the leading ERP for metalcasters, please get in touch with us using the form below.